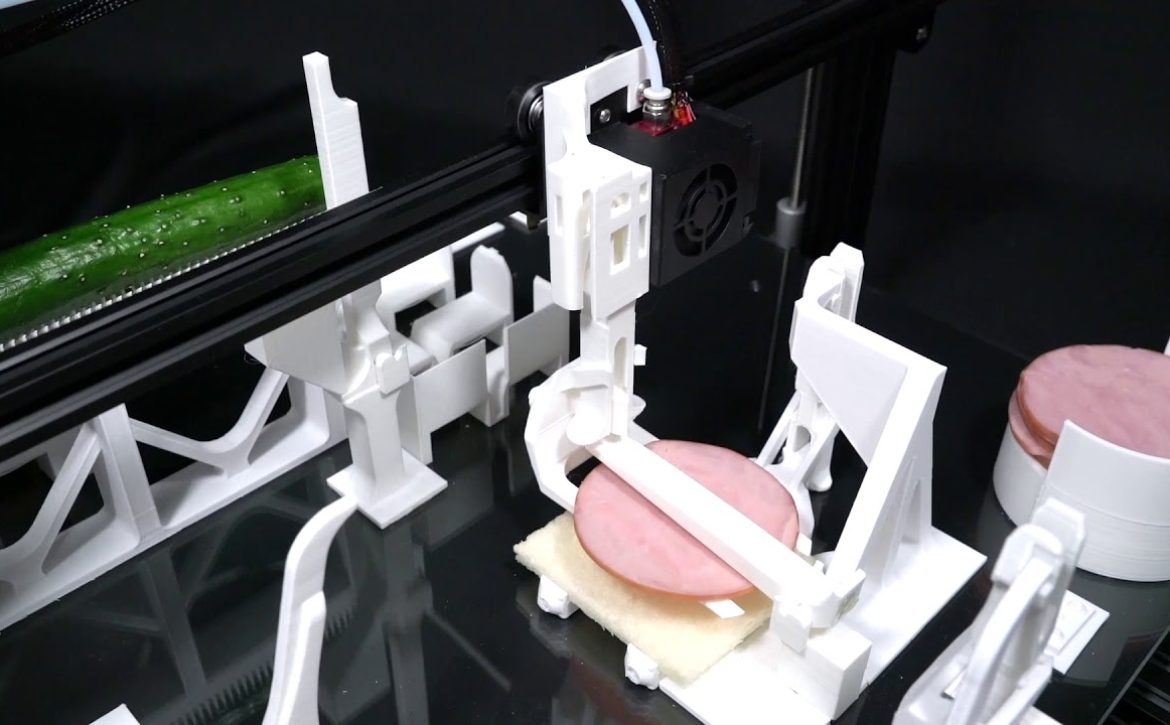

Researchers convert a 3D printer into a sandwich making machine

Mechanical engineer Yuto Kuroki of Meiji University and colleagues hacked a 3D printer head to use as a 3-axis robotic manipulator to enable more advanced fabrication techniques like assembling and actuating parts as opposed to merely printing them. They call it the Functgraph and to demonstrate it’s abilities they did what all serious researchers do: they used it to make a bologna sandwich.

To achieve these manipulations, we customize a low-cost fused deposition modeling (FDM) 3D printer that can attach/detach printed end-effectors which change the function of the 3D printer head (e.g. grab, break, and rotate printed objects). These techniques afford the 3D printer to fabricate and assemble complete kinetic objects such as automatons without manual processing (i.e. removing support materials and assembling objects). We conclude that a small modification to a standard 3D printer, allows us to fabricate and assemble objects without human intervention.

Not only does it make the sandwich, it makes the thing that makes the sandwich. The next logical step is to get the 3D printer to print and assemble another 3D printer and then convert that 3D printer into a sandwich-making machine.

Keep going for videos of the Functgraph in action; including making a sandwich, folding clothes, and assembling a toy car.

Read More